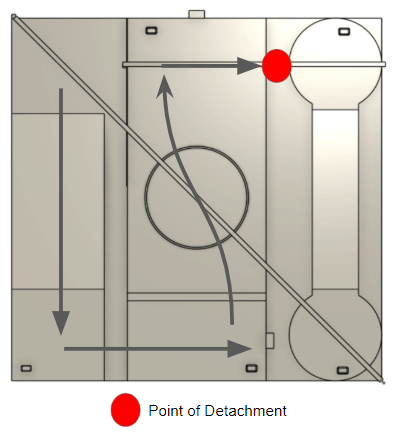

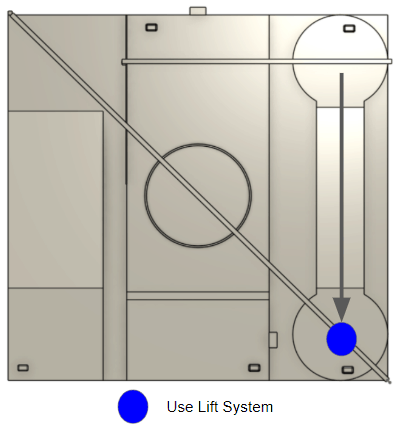

Planned Trajectories

Before taking a look at specific system components, it is worthwhile to observe the trajectory of each robot as this determines what systems each of the two robots will need throughout their duration of the competition course.

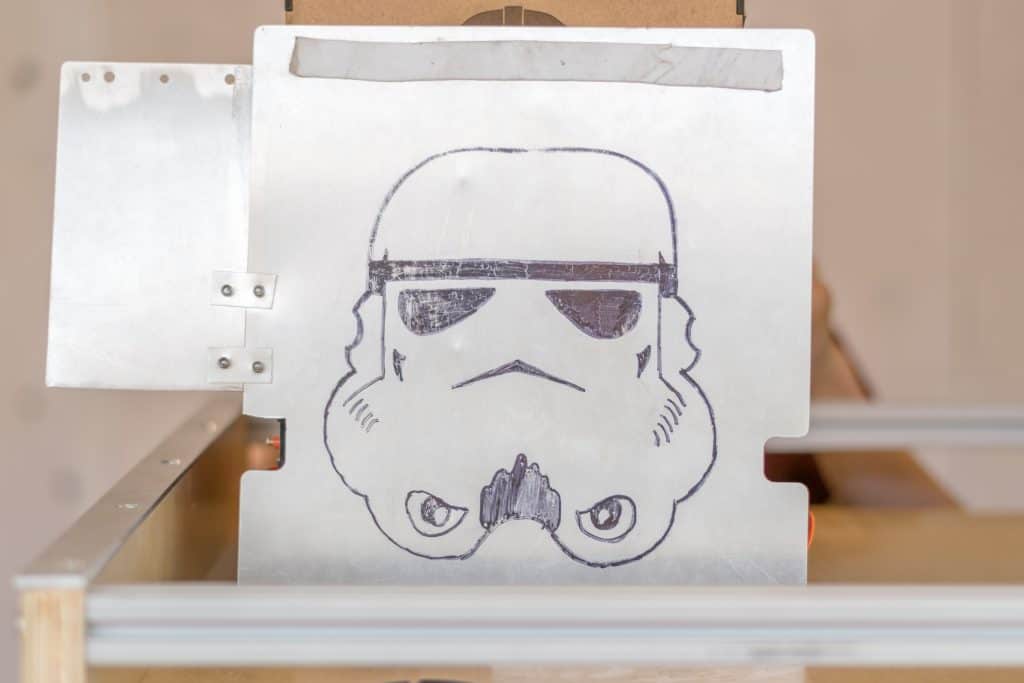

Claw Mechanism

Since we are using two robots, there are two heights at which we need to rescue Ewoks at – one where Vader Bot is on top of Trooper Bot, and the other when Vader Bot has detached. Therefore, we needed a dynamically adjustable claw to account for the height changes.

By utilizing a servo connected to a claw with an aluminum linkage, we were able to make the angle at which we grabbed the Ewoks modular – furthermore, with 40 N-cm of torque, the servos we used had more than enough power to complete a 180 degree rotation and place the rescued Ewok inside Vader Bot.

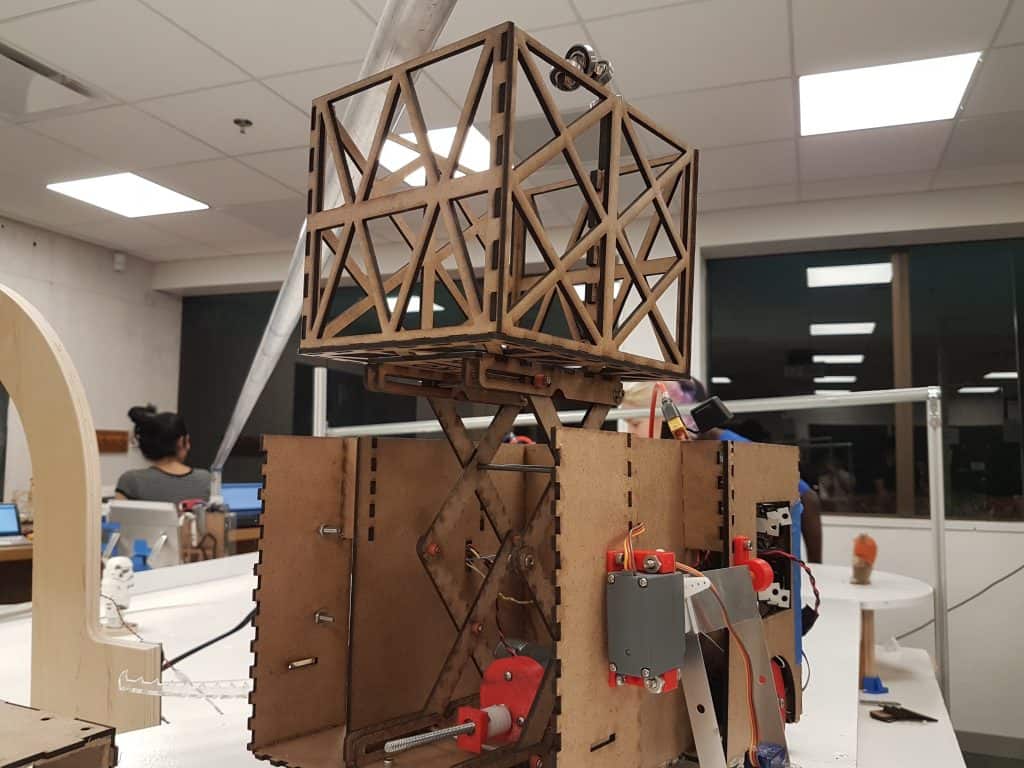

Scissor Lift

At the end of the competition course, a zipline leading down to the starting position was available for use. Our team decided to collect our rescued Ewoks in a basket along the competition course and ultimately send it down the zipline.

In order to raise the basket to the zipline level, 16 inches off the platform directly below it, a scissor lift was designed and used. The scissor lift utilized a lead screw, powered by a Geared Barber Coleman, to raise and lower the lift. Eight 12cm linkages were used at maximum extension to raise the basket to the zipline level.

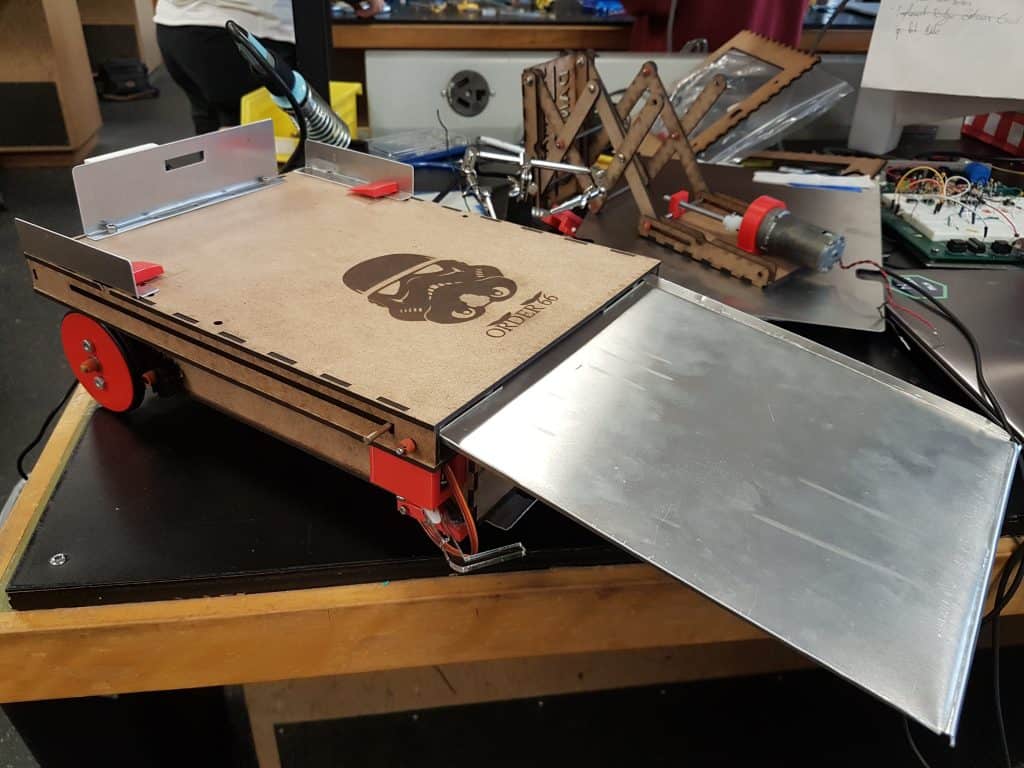

Gap Crossing

On the competition surface, the first main obstacle we face is a 6 inch gap. While some teams decided to design and use treads to cross this gap, we simply chose to drop a bridge and create a pathway for our robot.

Using a 3mm thick aluminum sheet metal that was water-jet, a bridge wide and long enough for the entirety of our robot to safely cross was made. This bridge was held in place with two servos at the front of Trooper Bot. In our algorithm, we aligned our robot to be perpendicular to the gap, dropped the bridge, drove over it, and continued on with the rest of the course.

Bridge Extrusion

As part of our detachment sequence, a sheet of aluminum shoots out of Trooper Bot to overcome a 6 inch x 2 inch gap on which Vader Bot simply rolls off of onto the second part of the competition surface.

Inside Trooper Bot two strings were securely tied to the slider rod connected to the extrusion platform, which were also fastened to a GM3 motor. When the signal for detachment was received, the motor became powered and started coiling the string around the motor axis, resulting in the extrusion of our platform.